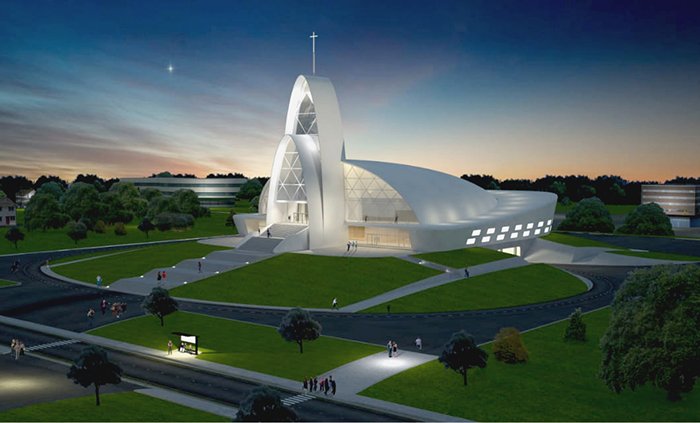

In the outskirts of Dimapur, Nagaland, Chekiye village is witnessing a remarkable journey of growth and unity. Guided by the founder’s vision, the new church blends Baptist tradition with modern steel architecture, embodying a unique ‘curved’ design. With a seating capacity of 5,000, this G+1 structure, inspired by Noah’s Ark.

Chekiye, situated on the outskirts of Dimapur town in Nagaland, is a suburban village founded by Chekiye Zhimomi. Over the years, the village population and the church congregation have grown, leading to the inadequacy of the seating capacity in the existing old church building, despite several renovation and expansion efforts.

In response to this challenge, a collective decision emerged among the members to construct a new church building. Guided by the aspirations of the village’s founder, the new edifice embraces a captivating and modern design, characterised by a distinct ‘curved’ shape. This architectural choice not only addresses the current needs, but also resonates with the founder’s vision for a spiritual haven that stands as a testament to the village’s growth and unity.

The new church building, blending Baptist Christian tradition with modern steel architecture inspired by Noah’s Ark, boasts a seating capacity of 5,000. The design features twin ‘Arch Towers’ forming a spire, a dome roof with a 2D curvature resembling a vertically cut half egg, and tapered side walls with staggered windows for an ark appearance.

This G+1 structure utilises steel for the upper level, offering a 57 m clear span, 87 m length, and 18 m height. The main auditorium, with a stepped gallery, houses a 262 sq m stage for large choir groups and ceremonial events.

The building includes a spacious entrance lobby, large corridors, office space, sound/projector room, stage back room, and an extensive basement/ground floor area for facilities like a cafeteria and Sunday school, enhancing its grandeur.

Building the Ark

The first challenge was the architectural concept which can do justice to the unique requirements of the Church members. LT Designs of Dimapur rose to the occasion, presenting a concept rooted in the iconic shape of Noah’s Ark, as recounted in biblical lore. This unique design not only honours the sacred narrative, but also serves as a fitting symbol of unity and faith for the congregation of Chekiye.

Following the conceptualisation, the structural designing and detailing of the distinctive shape, coupled with the construction of the RCC structure utilising local resources, presented intricate hurdles. Moreover, the manufacture and transportation of the pre-engineered and pre-fabricated structures were hampered by logistical constraints arising from the remote geographical location.

Undoubtedly, the most daunting task emerged during the structure’s erection and installation. The unique shape and expansive clear span posed significant challenges, exacerbated by the scarcity of suitable

capacity cranes.

Embracing curves

Given the unique shape of the building and considering factors such as available local resources, time constraints, and budget limitations, a thorough exploration of diverse design and fabrication approaches was undertaken.

Various concepts like spaceframe construction, tubular trusses, and portal-frame construction using built-up sections, were carefully considered.

Each approach was evaluated while being mindful of the constraints imposed by the local

context, project timeline, and budgetary considerations.

The distinctive semi-egg shape of the roof presented an inherent advantage by naturally creating a sequence of arches with varying heights and spans, serving as load-bearing elements. To address the challenge of large spans, pre-engineered double

‘I’ sections were employed as arch elements. This minimised the depth of the arch members and conferred strength against lateral bending arising from the continuously changing profile. Additionally, it ensured lateral stability during the erection phase.

While the arches themselves exhibit exceptional structural stability, their design generates substantial lateral thrust. To counteract this force, supporting RCC members and base plates were designed carefully.

Winds of resilience

The selection of arches proved to be a natural and effective choice in achieving the desired egg shape. Constructed with double I-section elements in pre-fabricated steel, these arches offered a reduced depth, allowing for an impressive clear height of the roof. The use of a higher grade of steel with a yield strength of 345 MPa created lighter members, enhancing the overall efficiency of

the structure.

The lighter weight of the roof is particularly significant in the seismic context of Dimapur, located in Seismic Zone V, the most severe earthquake zone in India.

The reduced weight translates to lower seismic forces. Additionally, the anticipated high wind speed of 50 m/s, the highest in the country, poses challenges in terms of uplift forces. However, the thrust generated by the arch is partly compensated by wind deformations in the opposite direction, providing a measure of resilience against these forces. Furthermore, the use of steel members in the construction of the stepped gallery contributes to a lesser mass, resulting in reduced earthquake forces.

Tech-driven mastery

Nagaland, a developing state, faces constraints in fabricating pre-engineered steel buildings, particularly those with large spans. Consequently, steel fabrication was outsourced to a different location where higher grades of steel and advanced welding techniques like Submerged Arc Welding (SAW) could be utilised.

The entire structure underwent modelling on Building Information Modeling (BIM) software, specifically TEKLA. This comprehensive approach facilitated the detailed modelling of each member, including nuts and bolts, ensuring precise alignment with the envisioned shape of the double-curved roof.

Furthermore, all fabrication and erection drawings were also generated from this BIM model, ensuring accurate conformity to the complex shape of the roof. Notably, detailing the purlins to generate the desired surface presented a significant challenge.

Conquering nature

Undoubtedly, undertaking a project of this nature in the northeast states, barring Assam to some extent, poses distinctive challenges. The notable absence of industrial infrastructure and skilled labour, coupled with issues related to road connectivity, distance, and local ‘disturbances,’ along with the annual challenge of heavy rains lasting 3-4 months, demanded an exceptionally meticulous and forward-thinking approach to planning.

Given the unique shape of the

building, digital construction software was leveraged and detailed planning for all project activities was conducted. Regular reviews of these plans ensured that the project team could adapt to the dynamic challenges posed by the region’s circumstances.

The success of the project in such a challenging environment hinged on the fusion of cutting-edge technology, planning, adaptive management. This approach not only navigated the hurdles inherent to the NE context, but also ensured the flawless execution of the architectural design.

“This project was a huge learning experience and with the lessons learnt during the successful execution of the same, we are now confident of undertaking efficiently, even bigger and more complex projects anywhere in India.”